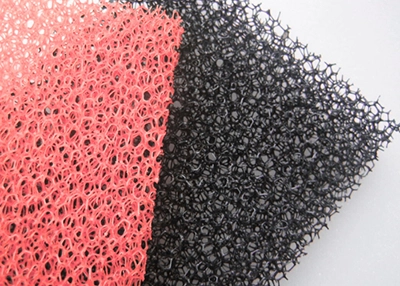

Open & Closed Cell Foam Gaskets

Foam gaskets provide flexible sealing, cushioning, and vibration dampening for industrial applications. The cellular structure (whether open cell or closed cell) determines how the material compresses, resists moisture, and recovers after use. We work with a wide range of foam gasket materials, from standard neoprene and EPDM to specialized options like Poron® microcellular urethane and conductive EMI foams, all customizable in density, thickness, and color.

Certified Foam Gasket Manufacturer with 45+ Years Experience

Gasket and Seal Fabricators specializes in precision-cut foam gaskets across all cellular materials. We serve electronics enclosures, HVAC equipment, automotive assemblies, medical devices, and industrial machinery. Basically, any application where dust sealing, moisture resistance, shock absorption, and vibration control are critical.

Closed Cell Foam Gaskets

Closed cell foams feature sealed, independent cells that block moisture, resist air infiltration, and stand up to environmental exposure. Materials like neoprene, EPDM, cross-linked polyethylene, and EVA foam provide excellent weather resistance and dimensional stability for outdoor equipment, electronic enclosures, and marine applications. The firmer structure maintains consistent sealing pressure and resists compression set under sustained loads.

Open Cell Foam Gaskets

Open cell foams have interconnected cells that create a lightweight, highly compressible structure. These materials (including polyester, polyether, and polyurethane foams) conform easily to irregular surfaces and bounce back to their original thickness after repeated compression. They’re ideal for dust sealing, sound absorption, vibration dampening, and packaging in controlled indoor environments.

Custom Foam Configurations

Beyond standard open and closed-cell gaskets, we provide application-specific foam solutions: filter foams for air and fluid filtration, acoustic foams for noise reduction, convoluted foams for enhanced cushioning, and specialty polymer blends. All materials are available with or without pressure-sensitive adhesive backing, custom colors, UL94 flammability ratings, and FDA-compliant formulations for food and medical applications.

Specialty Performance Foam

We fabricate advanced foam materials for demanding technical applications. Poron® microcellular urethane combines exceptional mechanical strength with superior compression performance. Multi-planar EMI foam provides electromagnetic shielding along with environmental sealing. Silicone foam handles extreme temperatures from -100°F to 500°F while maintaining flexibility and compression resistance. Common for medical, aerospace, and high-heat industrial uses.

Complete Material Selection from Leading Manufacturers

Our closed cell foam selection includes pure EPDM (excellent ozone and UV resistance), neoprene (oil and weather resistance), Buna-N nitrile (petroleum product resistance), industry-standard neoprene/SBR/EPDM blends, silicone foam (extreme heat applications), and Viton fluoroelastomer (superior chemical resistance).

Open cell options include neoprene and natural rubber foams for sound and vibration dampening, crushed semi-open cell foam for maximum compressibility, standard polyurethane for economical dust sealing, and reticulated filter foam (10-80 PPI) in polyester or polyether for filtration applications.

Every material is available with pressure-sensitive adhesive backing, custom colors, and formulations meeting UL94, FDA, and industry specifications. Our team guides you to the right material based on your operating environment, chemical exposure, temperature requirements, and compression needs.

One Call, Complete Solutions

Talk to our technical team about material selection, fabrication options, and pricing for your project. Click the number below to speak to our experts!