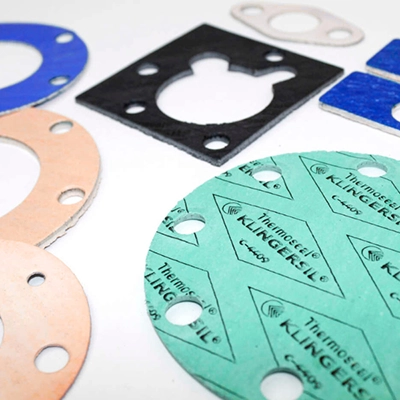

KLINGER Gaskets

KLINGER compressed fiber gasket materials combine synthetic and inorganic fibers with engineered binders to deliver exceptional sealing performance across demanding industrial applications. Originally developed as the world’s first compressed non-asbestos fiber gasket material, KLINGERSIL sheets provide superior creep resistance, excellent chemical compatibility, and reliable high-temperature performance. These materials are manufactured through precision calendaring processes that produce consistent density and compressibility while maintaining dimensional stability under extreme pressures and thermal cycling.

Trusted KLINGER Gasket Fabricator for 45+ Years

As a trusted fabricator for KLINGER Thermoseal, we have access to premium KLINGER materials available only through their exclusive US license. We specialize in precision-cut KLINGERSIL compressed fiber gaskets that stand up to harsh chemical environments. These high-performance gaskets handle continuous operating temperatures of 400-500°F and can withstand temperature spikes up to 850°F.

KLINGERSIL Compressed Fiber Gaskets

Premium compressed non-asbestos fiber materials combining aramid, fiberglass, and synthetic fibers with nitrile binders for general-purpose industrial sealing. KLINGERSIL C-4401 provides universal sealing with excellent chemical resistance for water, steam, oils, and moderate chemicals. KLINGERSIL C-4430 offers enhanced performance for applications with superior stress relaxation. KLINGERSIL C-4433, the ultimate steam sheet, delivers outstanding load-bearing properties and creep resistance for steam service up to 500°F and liquid sealing to 800°F.

High-Performance Specialty Gaskets

Advanced KLINGERSIL formulations engineered for extreme operating conditions. C-4500 carbon fiber gaskets provide premium high-pressure performance for alkaline media and superheated steam in pulp and paper operations. C-8200 chemical-resistant sheets offer an economical alternative to PTFE materials with excellent resistance to strong acids, alkalis, ketones, and refrigerants. These specialty grades meet TA-Luft clean air standards when installed according to VDI guidelines and deliver extended service life in corrosive chemical processing environments.

KLINGER Top-Chem PTFE Gaskets

Expanded PTFE and modified PTFE gasket materials offering maximum chemical resistance with minimal creep under bolt load. These “no-creep” formulations provide tight sealing at low surface pressures with superior resistance to strong acids, caustic solutions, and aggressive solvents across temperatures from -328°F to +500°F. FDA-compliant grades available for pharmaceutical and food processing applications requiring chemical inertness and easy cleanability.

KLINGER Graphite and Mica Gaskets

Flexible graphite laminates (Top-Graph) provide exceptional high-temperature sealing from -200°C to +460°C with broad chemical resistance for flange applications in refineries and power plants. KLINGER Milam mica laminates withstand continuous temperatures to 1650°F, making them the preferred choice for extreme heat applications including exhaust manifolds, turbines, turbochargers, and industrial heat exchangers where conventional materials fail.

Serving Critical Industries with Certified Quality

KLINGER materials deliver proven performance across industries where sealing failure isn’t an option. We’re both ISO 9001 and AS9100 registered, ensuring the rigorous quality standards, traceability, and documentation that your critical applications demand.

Industries we serve:

-

- Aerospace: Reliable sealing against aviation fuels and hydraulic fluids in extreme altitude conditions

- Compressors: Exceptional high-temperature performance and corrosion resistance under continuous pressure cycling

- Material Handling: Effective vibration dampening and shock control for conveyors and heavy machinery

- Military & Defense: Protection for electronics in ground vehicles and tactical equipment exposed to combat conditions

- Oil & Gas: Materials that withstand corrosive crude, sour gas, saltwater, and temperature extremes from wellheads to refineries

- Petrochemical: Gaskets for reactor vessels, heat exchangers, and piping systems handling aggressive acids, caustics, and solvents at high temperatures

Our certifications back every gasket we fabricate with consistent quality control, complete documentation, and the technical support your compliance requirements demand.

One Call, Complete Solutions

Need expert guidance? Talk to our team about material selection, fabrication methods, and pricing for your next project.