Viton Gaskets

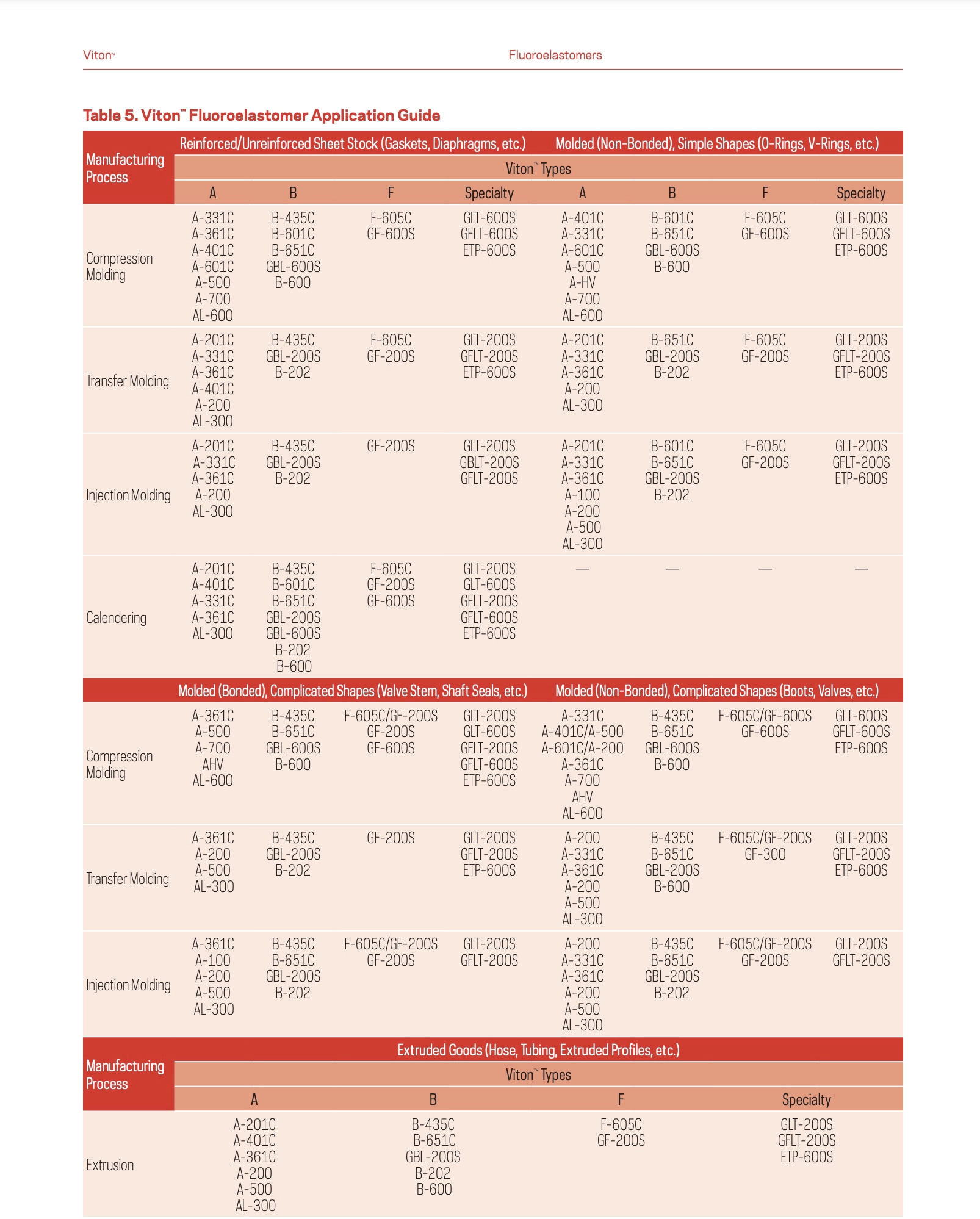

As a leading Viton gasket manufacturer, we fabricate custom gaskets and seals in multiple FKM compounds — including A, B, F, and GLT grades — plus FFKM perfluoroelastomers for ultimate chemical resistance.

All products meet stringent aerospace specifications including AMS-R-83485 and are manufactured to exact tolerances using advanced molding and fabrication techniques.

Your Trusted Viton Gasket Manufacturer

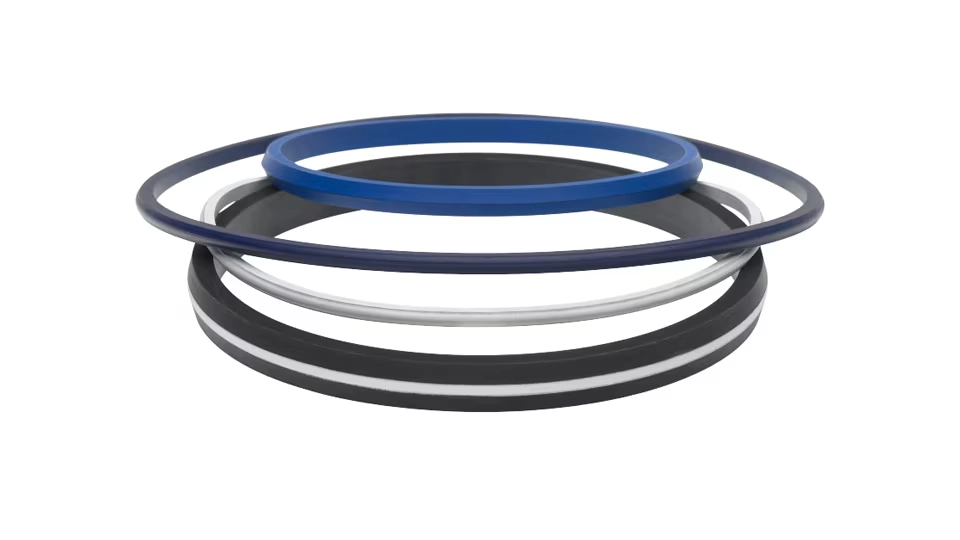

Viton O-Rings & Cord Stock

Precision-molded Viton o-rings in standard AS568 and metric sizes, plus continuous cord stock for field fabrication. Available in multiple FKM compounds for temperature ranges from -15°F to +400°F with exceptional chemical resistance.

FFKM Perfluoroelastomer Seals

Ultra-high-performance FFKM seals offering universal chemical compatibility and temperature resistance to 600°F. Critical for semiconductor, pharmaceutical, and chemical processing applications requiring absolute purity.

Die Cut Viton Gaskets

Die-cut and water-jet fabricated FKM gaskets in complex geometries from 1/64″ to 1/4″ thick. Available in multiple grades including Viton A (66% fluorine), B (68% fluorine), and F (70% fluorine) with durometer ratings from 55 to 90 Shore A.

Molded FKM Components

Custom molded Viton seals available through our trusted molding partners using compression, transfer, and injection molding processes. We can coordinate complex geometries manufactured to RMA A2 precision tolerances in black, brown, or white compounds, with custom color compounding available upon request.

FDA-Compliant Compounds

Food-grade and pharmaceutical-approved Viton compounds meeting FDA 21 CFR 177.2600 requirements. Clean-room manufactured with full material traceability for validation in regulated food processing and pharmaceutical applications.

Specialty FKM Grades

Advanced compounds including Low temperature FKM for flexibility and sealing performance in sub-zero environments, Extreme grade for enhanced plasma resistance, Base grade for improved processing characteristics, and Viton Sponge for cushioning applications requiring chemical resistance with compressibility.

Choosing the Right Material

FKM vs FFKM Selection Guide

Need Material Guidance?

Connect with our specialists to determine what’ll meet your performance needs.

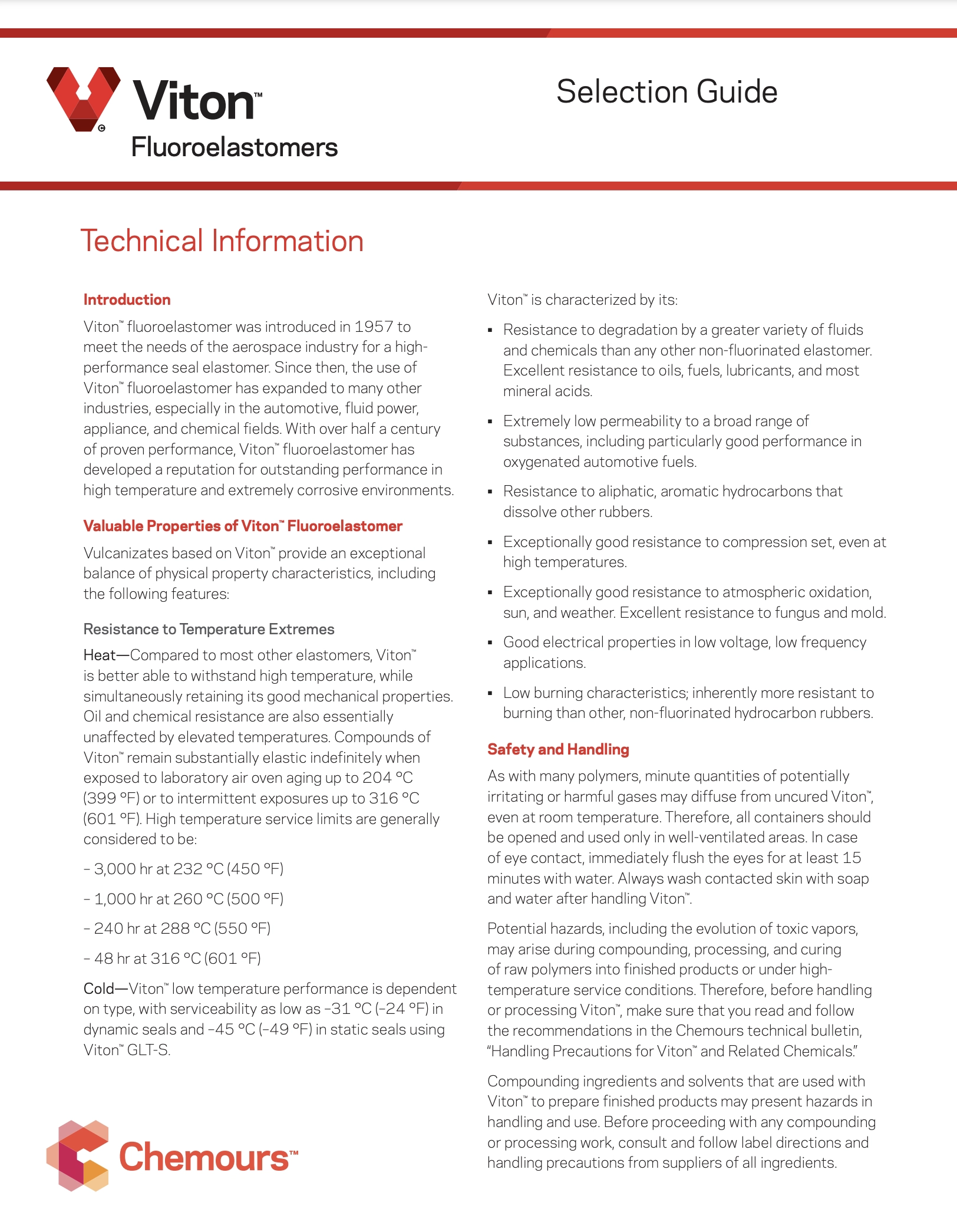

Why Fluoroelastomer (FKM) Works for Most Projects

Most challenging applications find their solution in FKM elastomers. These materials tackle high chemical resistance requirements and temperatures up to 400°F (204°C). Thanks to their 66-70% fluorine content, FKM seals resist fuels, oils, solvents, and corrosive chemicals. It’s ideal for automotive, industrial, and oil/gas applications where you need more than standard rubber, but still want to save on costs.

Why Some Applications Need Perfluoroelastomer (FFKM)

Some applications simply can’t compromise on seal performance. When you’re dealing with universal chemical compatibility across 1,800+ chemicals and solvents, or temperatures that push beyond 400°F up to 600°F (325°C), perfluoroelastomers are your only option. The fully fluorinated backbone creates unmatched chemical inertness, making FFKM the go-to choice for many semiconductor, pharmaceutical, and aerospace applications.