Products

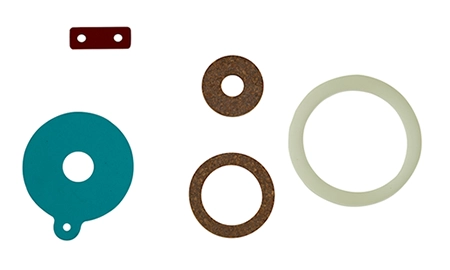

Whether you need a single rubber seal for a prototype or thousands of rubber gaskets for production, we’ve got you covered. Our rubber seals and gaskets are hard at work in HVAC systems, oil & gas operations, electrical equipment, medical devices, and aerospace applications. Basically, if it needs to be sealed, we’ve probably made a gasket for it.

Thanks to our supplier relationships, we have access to specialty compounds that most shops can’t get. Sometimes your application needs something beyond basic rubber gasket materials — maybe it’s extreme temperatures, aggressive chemicals, or unique installation requirements. We work with you to find the exact material that will solve your specific problem.

Better material selection means longer-lasting parts, fewer failures, and easier installation. We can cut anything from tiny precision pieces to gaskets several feet across, and we handle everything from one-off prototypes to full production runs:

- Nitrile

- Cork

- Silicone

- FKM (Viton)

- Fiberglass

- Neoprene

- EPDM

- PTFE (Teflon)

- Urethane

- Plastic

- Fish paper

- and many others

- Nitrile

- Cork

- Silicone

- FKM (Viton)

- Fiberglass

- Neoprene

- Polyurethane

- EPDM

- PTFE (Teflon)

- Urethane

- Plastic

- Fish paper

- Foam

- And many others!

Gaskets

Custom Rubber Gaskets

Die Cut Rubber Gaskets

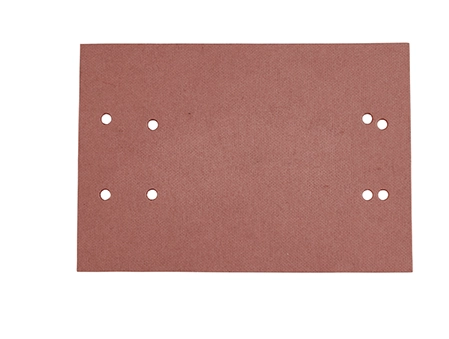

Our die cut capabilities include steel-rule, steel-cast, and kiss cut products. Our dies are able to hold tight tolerances across a wide range of sizes. We reuse these dies for future production runs which saves our customers money.

Pressure Sensitive Adhesive (PSA)

In some cases your rubber gasket must be adhesively bonded during its installation. GSF specializes in these “peel-and-stick” gaskets and can laminate most materials with adhesive backing. We work with the highest quality brands such as 3M and Berry specialty tapes to ensure reliability.

Vulcanized & Spliced Gaskets

Vulcanizing uses heat, pressure, and uncured rubber to bond the two ends into a continuous part. Applications include O-rings, tubing, and other products with a space for the free-flowing passage of air to the gasket. GSF is well-known for vulcanizing electric transformer gaskets.

Specialty Gaskets

We also offer a wide variety of specialty rubber gaskets: lathe cut, extruded, molded, and many more!

Seals

Rubber Seals & O-Rings

O-Rings

Trusted O-Ring supplier for our customers in the medical, electrical, aerospace, HVAC-R, oil & gas, and many more industries. As an authorized distributor for the industry’s top brands you can trust that your parts are the highest quality for the application.

O-Ring Compounds

The base elastomer of an O-ring is one of the main factors which enables a given compound to resist heat, chemical, and other physical influences. GSF supplies O-rings made from commonly used or exotic polymers to suit your project’s application.

Oil Seals

Oil seals are used to seal the environment around a rotating shaft and keep an oil-based lubricant inside an axle, engine, etc. GSF is a well known supplier of Parker Oil Seals in the Midwest.

Specialty Rubber Seals

We also offer a wide variety of specialty rubber seals like backup O-rings, super O-lube, O-ring cord, quad rings, D-rings, filter seals, etc.

Our Recent Fabrication Projects

Your Source for Rubber Gaskets, O-Rings & Seals

Fast Turnaround, Faster Shipping

Rapid product-to-market turnaround with expedited shipping to anywhere in the continental US. Most rubber gasket orders ship within 3-5 business days.

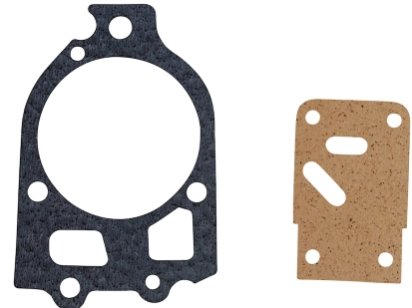

Fire Alarm Panels

Our customer approached us to supply rubber seal components for their fire alarm panels. Gasket & Seal Fabricators sourced polyurethane foam and applied PSA backing for ease of installation. After a multi-step manufacturing process, we were able to kiss cut 2 parts nested into one die to save money for the customer.

Overhead light gasket

A customer approached us with an idea on creating a rubber gasket allowing for a ‘channel’ that would divert water away from sensitive electrical components. Our team was able to provide a prototype using kiss-cutting techniques that the customer now applies to all of their overhead lighting fixtures.